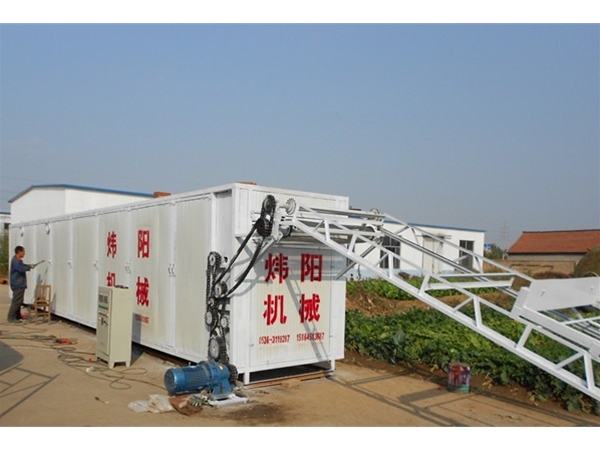

Product Name:QG series airflow dryer

This type of equipment is suitable for a variety of materials, in addition to the materials mentioned in the basic model, there are also: A B. C intermediate, A B. S resin, A S. C. White carbon black, benzopyrazole ketone, tea meal, oxalic acid catalyst, promoter m.d.m, catalyst, precipitated carbon powder, acetaminophen, aminosalicylic acid, Doraemon, phthalic acid, diethylphenylammonium, titanium dioxide, activated carbon, sodium fluorosilicate, fluorite ore, by-product ammonium sulfate, silica gel powder, synthetic resin, calcium phosphate, polypropylene resin, aureomycin, sodium metasilicate, coffee grounds, oral grape bran, sodium sulfate, sulfide ore, phosphate ore powder, orchid BB, P V. C. Molten phosphate fertilizer, tetracycline, ferric oxide, calcium carbonate, ilmenite, copper ore, potato chips, tail coal, stearate, corn protein, pharmaceuticals, agents, iron oxide, wine residue, etc.

working principle

A fan with dispersing function is particularly suitable for airflow drying operations of thermal sensitive materials. The high-speed rotating fan impeller can crush wet or even agglomerated materials until they are dispersed. During the dispersion process, the material is stirred and mixed simultaneously, and then flows parallel to the hot air flow. This type of equipment is suitable for drying filter cake clumps, but still belongs to surface moisture materials with a moisture content of ≤ 40%. If the processing capacity is large or the finished product requires drying to below 15%, secondary airflow drying can be used. When the moisture content of the material exceeds 40% but ≤ 60%, feeding is difficult and a mixer should be used to reduce the moisture content of the feed by mixing the dry material. At this time, the total output of the drying equipment will decrease significantly, which is not cost-effective economically

Therefore, users should first use mechanical methods (centrifugal dehydration or pressure filtration) to minimize the moisture content of the feed as much as possible to ensure the smooth progress of the drying operation.

Technical parameters:

| model | Evaporated moisture Kg/h | Installed power Kw | area covered

(M2) | Height m |

| QG50 | fifty | seven | twenty | fourteen |

| QG100 | one hundred | thirteen | thirty-two | fourteen |

| QG200 * | two hundred | twenty-one | forty | fifteen |

| QG250 | two hundred and fifty | twenty-four | sixty-four | fifteen |

| QG500 | five hundred | forty-three | ninety-six | eighteen |

| QG1000 * | one thousand | one hundred | one hundred and twenty | eighteen |

| QG1500 * | one thousand and five hundred | one hundred and fifty | two hundred | twenty |

Note: Items marked with an asterisk (*) indicate secondary drying, installed power, and floor area, which are calculated using steam heating method